In rough terrain forklifts, the frame is the foundation of strength, safety, and long-term performance. And not all frames are built the same.

The Landtiger35 features a fully integrated frame structure, made from thick, high-grade steel plates that are formed from a single piece—not pieced together. There are no major weld seams in the load-bearing sections, reducing stress points and increasing structural life.

In contrast, the T35 low-cost model uses small steel plates welded together to form the frame. This manufacturing approach reduces cost but significantly increases the risk of:

- Cracks at weld joints

- Frame deformation under load

- Reduced structural integrity over time

On average, the Landtiger35’s frame weighs 500 kg more than T35's, thanks to thicker materials and a more robust design standard. It's built not just for basic transport—but for serious off-road work in construction, mining, and agriculture.

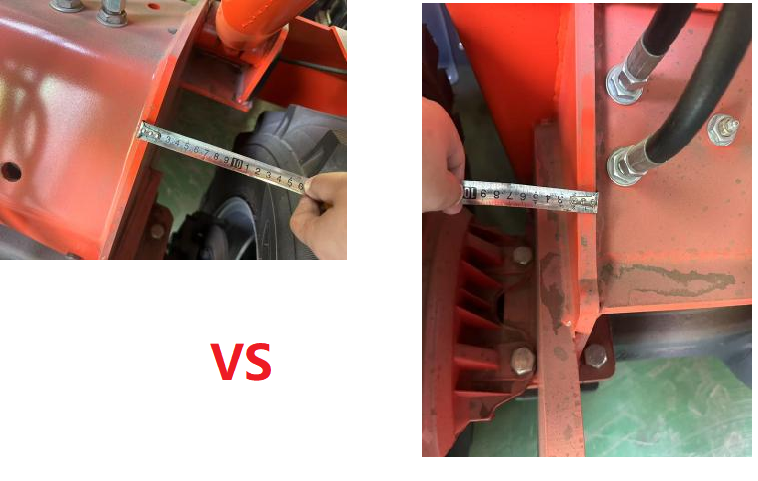

We provide side-by-side photo comparisons of key frame areas from both models, showing differences in thickness, structure, and build quality.

In summary:

- Landtiger35: Thick, one-piece steel plates, robotically formed, minimal welding

- T35: Thin welded patchwork plates, lower structural grade

- Result: 500kg difference = massive durability advantage